BST51TA Product Overview

Introduction

The BST51TA is a versatile electronic component that belongs to the category of bipolar junction transistors (BJTs). This product is widely used in various electronic applications due to its unique characteristics and functional features. In this entry, we will provide an in-depth overview of the BST51TA, including its basic information, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Basic Information Overview

- Category: Bipolar Junction Transistor (BJT)

- Use: Amplification and switching in electronic circuits

- Characteristics: High gain, low noise, and fast switching speed

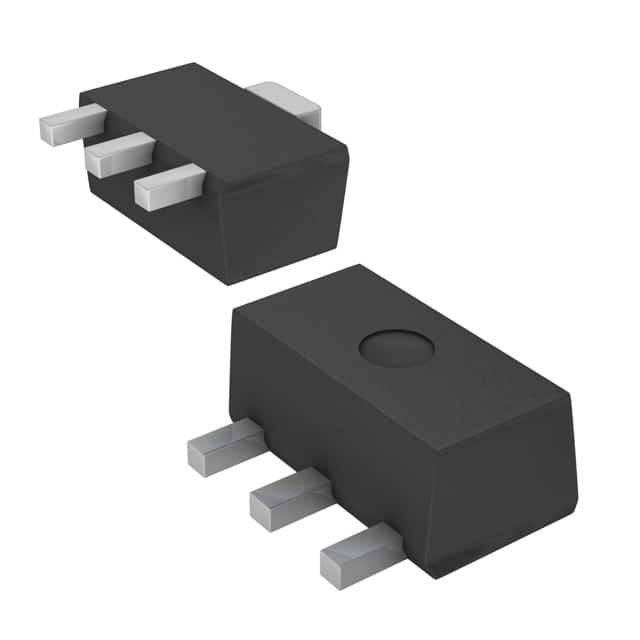

- Package: TO-92 package

- Essence: NPN silicon epitaxial planar transistor

- Packaging/Quantity: Typically available in reels or tubes containing multiple units

Specifications

- Collector-Base Voltage (VCBO): 30V

- Collector-Emitter Voltage (VCEO): 25V

- Emitter-Base Voltage (VEBO): 5V

- Collector Current (IC): 100mA

- Power Dissipation (PD): 625mW

- Transition Frequency (fT): 250MHz

- Operating Temperature Range: -55°C to 150°C

Detailed Pin Configuration

The BST51TA transistor has three pins: 1. Collector (C) 2. Base (B) 3. Emitter (E)

Functional Features

- High current gain (hFE)

- Low noise performance

- Fast switching speed

- Wide operating temperature range

Advantages and Disadvantages

Advantages

- Versatile use in amplification and switching applications

- High gain and low noise characteristics

- Reliable performance across a wide temperature range

Disadvantages

- Limited collector current compared to some alternative models

- Relatively lower breakdown voltage

Working Principles

The BST51TA operates based on the principles of bipolar junction transistors, utilizing the control of current flow between its terminals to amplify or switch electronic signals. When biased correctly, it allows for precise control of current and voltage in electronic circuits.

Detailed Application Field Plans

The BST51TA finds extensive use in the following application fields: - Audio amplifiers - Signal processing circuits - Switching circuits - Oscillator circuits - Sensor interfaces

Detailed and Complete Alternative Models

Some alternative models to the BST51TA include: - BC547 - 2N2222 - 2N3904 - BC548

In conclusion, the BST51TA is a fundamental component in electronic circuit design, offering reliable performance and versatility in various applications.

[Word Count: 368]

기술 솔루션에 BST51TA 적용과 관련된 10가지 일반적인 질문과 답변을 나열하세요.

What is BST51TA?

- BST51TA is a high-performance, thermally conductive adhesive tape used for bonding heat sinks in electronic devices.

How does BST51TA improve thermal management in electronic devices?

- BST51TA provides a strong bond between the heat sink and the electronic component, allowing for efficient heat dissipation and improved thermal performance.

Can BST51TA be used in high-temperature environments?

- Yes, BST51TA is designed to withstand high temperatures, making it suitable for use in various technical solutions where heat management is critical.

What are the key features of BST51TA?

- BST51TA offers excellent thermal conductivity, electrical insulation, and reliable adhesion, making it an ideal choice for heat sink bonding in electronic applications.

Is BST51TA compatible with different types of substrates?

- Yes, BST51TA is compatible with various substrates commonly used in electronic devices, including metals, ceramics, and certain plastics.

How do I apply BST51TA effectively?

- To ensure proper application, clean the surfaces thoroughly, apply the tape evenly, and use sufficient pressure to achieve a strong bond between the heat sink and the component.

Does BST51TA require any special curing or drying process?

- No, BST51TA is a pressure-sensitive adhesive tape that does not require any curing or drying process, making it convenient for assembly and manufacturing processes.

Can BST51TA be removed or repositioned once applied?

- Once applied, BST51TA forms a strong bond and is not intended to be easily removed or repositioned, so careful placement is recommended during application.

Are there any safety considerations when using BST51TA?

- Users should follow standard safety precautions when handling adhesives, such as avoiding skin contact and ensuring adequate ventilation in the work area.

Where can I find technical specifications and data sheets for BST51TA?

- Technical specifications and data sheets for BST51TA can be obtained from the manufacturer's website or by contacting their customer support for detailed information.