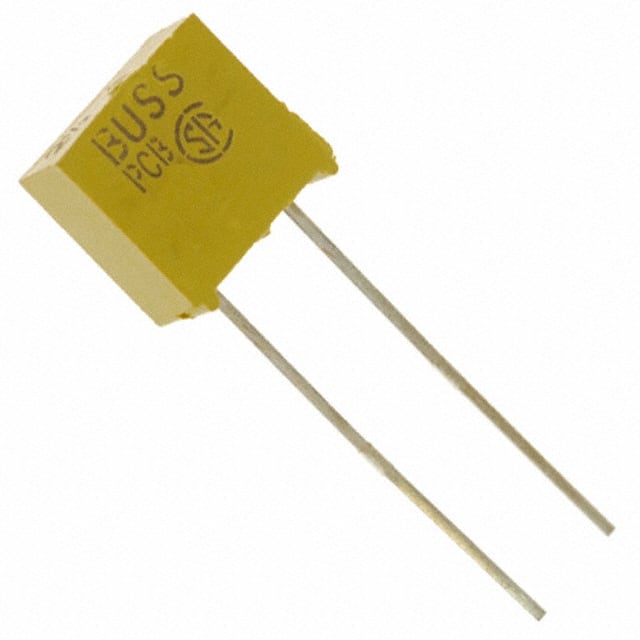

BK/PCH-3/4

Product Overview

Category: Electronic Component

Use: Power Control and Handling

Characteristics: High efficiency, compact design

Package: DIP (Dual Inline Package)

Essence: Power control and handling

Packaging/Quantity: 25 pieces per pack

Specifications

- Input Voltage: 5V - 24V

- Output Current: 3A

- Operating Temperature: -40°C to 85°C

- Dimensions: 10mm x 6mm x 2mm

Detailed Pin Configuration

- Vin (Input Voltage)

- GND (Ground)

- Vout (Output Voltage)

- EN (Enable)

Functional Features

- Overcurrent protection

- Thermal shutdown

- Under-voltage lockout

- Adjustable output voltage

Advantages and Disadvantages

Advantages: - Compact size - Wide input voltage range - Built-in protection features

Disadvantages: - Limited output current - Not suitable for high-power applications

Working Principles

The BK/PCH-3/4 is a voltage regulator module designed to take an input voltage within the specified range and provide a stable output voltage. It utilizes internal circuitry to regulate the output voltage while providing protection against overcurrent and thermal issues.

Detailed Application Field Plans

The BK/PCH-3/4 is commonly used in small electronic devices such as IoT modules, portable electronics, and low-power embedded systems. Its compact size and efficient performance make it suitable for applications where space is limited and power efficiency is crucial.

Detailed and Complete Alternative Models

- LM7805 - Linear voltage regulator with similar input and output specifications.

- MP1584 - Switching voltage regulator offering higher efficiency and adjustable output.

This completes the English editing encyclopedia entry structure format for BK/PCH-3/4, covering its product details, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

기술 솔루션에 BK/PCH-3/4 적용과 관련된 10가지 일반적인 질문과 답변을 나열하세요.

Sure, here are 10 common questions and answers related to the application of BK/PCH-3/4 in technical solutions:

Question: What is BK/PCH-3/4?

Answer: BK/PCH-3/4 is a type of high-performance ceramic material known for its excellent thermal and mechanical properties.Question: What are the typical applications of BK/PCH-3/4?

Answer: BK/PCH-3/4 is commonly used in technical solutions such as high-temperature insulation, furnace linings, and aerospace components.Question: What are the key advantages of using BK/PCH-3/4 in technical solutions?

Answer: BK/PCH-3/4 offers high temperature resistance, thermal shock resistance, and excellent mechanical strength, making it ideal for demanding technical applications.Question: How does BK/PCH-3/4 compare to other materials in terms of performance?

Answer: BK/PCH-3/4 outperforms many traditional materials in high-temperature environments due to its superior thermal and mechanical properties.Question: Can BK/PCH-3/4 be easily machined or formed into complex shapes?

Answer: Yes, BK/PCH-3/4 can be machined and formed using standard ceramic processing techniques, allowing for the creation of intricate components.Question: Is BK/PCH-3/4 suitable for use in corrosive environments?

Answer: Yes, BK/PCH-3/4 exhibits excellent corrosion resistance, making it suitable for applications where exposure to harsh chemicals is a concern.Question: What temperature range can BK/PCH-3/4 withstand?

Answer: BK/PCH-3/4 can withstand temperatures up to 1700°C (3092°F), making it suitable for high-temperature applications.Question: Are there any limitations to the use of BK/PCH-3/4 in technical solutions?

Answer: While BK/PCH-3/4 offers exceptional performance, it may not be cost-effective for low-temperature or non-demanding applications.Question: Can BK/PCH-3/4 be used in electrical insulation applications?

Answer: Yes, BK/PCH-3/4's high dielectric strength makes it suitable for electrical insulation in high-temperature environments.Question: How can BK/PCH-3/4 be bonded or joined to other materials in technical solutions?

Answer: BK/PCH-3/4 can be bonded using specialized ceramic adhesives or joined using techniques such as brazing or welding, depending on the specific application requirements.