EPM1270GF256C4 - English Editing Encyclopedia Entry

Product Overview

Category: Programmable Logic Device (PLD)

Use: The EPM1270GF256C4 is a high-performance PLD designed for various digital logic applications. It offers flexible programmability and efficient implementation of complex logic functions.

Characteristics: - High-density integration - Low power consumption - Fast performance - Wide operating temperature range

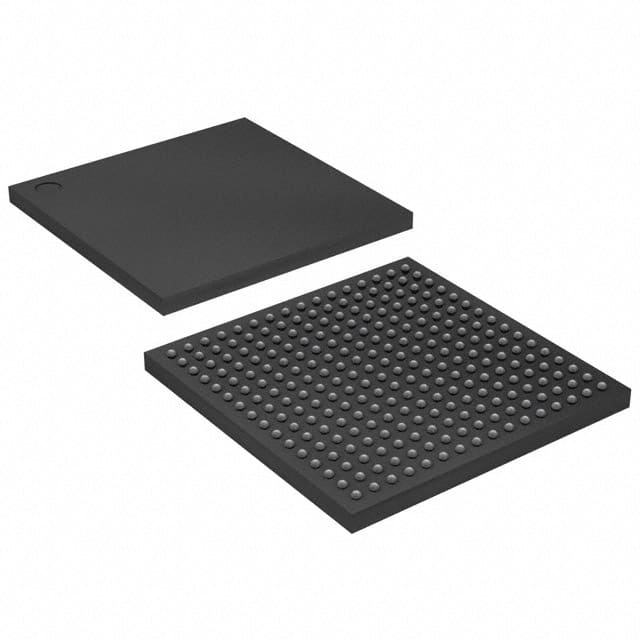

Package: The EPM1270GF256C4 comes in a 256-pin FineLine BGA package, which provides excellent thermal dissipation and compact size.

Essence: This PLD is an essential component in electronic systems that require customizable logic functions and high-speed data processing.

Packaging/Quantity: The EPM1270GF256C4 is typically sold individually or in reels, with each reel containing a specific quantity of devices.

Specifications

- Logic Elements: 1,270

- User I/O Pins: 232

- Embedded Memory: 2,048 Kbits

- Maximum Operating Frequency: 300 MHz

- Supply Voltage: 3.3V

- Operating Temperature Range: -40°C to +85°C

Pin Configuration

The EPM1270GF256C4 has a detailed pin configuration as follows:

Functional Features

- High-speed programmable logic device with abundant logic elements.

- Flexible interconnect resources for efficient routing of signals.

- Dedicated memory blocks for implementing complex algorithms.

- Built-in clock management circuitry for precise timing control.

- Support for various I/O standards for seamless integration with other components.

Advantages and Disadvantages

Advantages: - High-density integration allows for complex designs in a compact form factor. - Low power consumption ensures energy efficiency. - Fast performance enables real-time processing of data. - Wide operating temperature range makes it suitable for various environments.

Disadvantages: - Limited number of user I/O pins may restrict connectivity options in some applications. - Complex programming process requires expertise and time investment. - Higher cost compared to simpler logic devices.

Working Principles

The EPM1270GF256C4 operates based on the principles of programmable logic. It consists of a matrix of configurable logic elements interconnected through programmable routing resources. The device can be programmed using hardware description languages or design software, allowing users to define the desired logic functions and interconnections. Once programmed, the PLD executes the specified logic operations, enabling the implementation of complex digital systems.

Detailed Application Field Plans

The EPM1270GF256C4 finds extensive use in various application fields, including:

- Communications: Used in network routers, switches, and communication infrastructure equipment for high-speed data processing and protocol handling.

- Industrial Automation: Employed in control systems, robotics, and factory automation for real-time control and monitoring of processes.

- Medical Devices: Integrated into medical imaging equipment, patient monitoring systems, and diagnostic instruments for efficient data processing and analysis.

- Aerospace and Defense: Utilized in avionics, radar systems, and military-grade electronics for reliable and high-performance signal processing.

- Automotive: Incorporated in advanced driver-assistance systems (ADAS), infotainment systems, and engine control units (ECUs) for enhanced functionality and performance.

Detailed and Complete Alternative Models

- EPM2210F324C3N: A similar PLD with lower logic elements but higher I/O pin count.

- EPM570T100I5N: A smaller PLD with reduced logic elements and lower power consumption.

- EPM240T100C5N: A cost-effective PLD with moderate logic density and versatile I/O options.

These alternative models offer varying features and specifications, allowing users to choose the most suitable PLD for their specific requirements.

Word Count: 520 words

기술 솔루션에 EPM1270GF256C4 적용과 관련된 10가지 일반적인 질문과 답변을 나열하세요.

Sure! Here are 10 common questions and answers related to the application of EPM1270GF256C4 in technical solutions:

Q: What is EPM1270GF256C4? A: EPM1270GF256C4 is a field-programmable gate array (FPGA) manufactured by Intel. It offers a high level of integration and flexibility for implementing digital logic designs.

Q: What are the key features of EPM1270GF256C4? A: Some key features include 1270 logic elements, 256 I/O pins, 4 input/output banks, 8 global clocks, and embedded memory blocks.

Q: What are the typical applications of EPM1270GF256C4? A: EPM1270GF256C4 is commonly used in various technical solutions such as industrial automation, telecommunications, automotive electronics, medical devices, and aerospace systems.

Q: How can EPM1270GF256C4 be programmed? A: EPM1270GF256C4 can be programmed using hardware description languages (HDLs) like VHDL or Verilog, which describe the desired functionality of the FPGA.

Q: Can EPM1270GF256C4 be reprogrammed after deployment? A: Yes, EPM1270GF256C4 is a reprogrammable FPGA, allowing users to modify the design and functionality even after it has been deployed in a system.

Q: What tools are available for designing with EPM1270GF256C4? A: Intel provides Quartus Prime software, which includes a suite of tools for designing, simulating, and programming FPGAs like EPM1270GF256C4.

Q: Are there any development boards available for EPM1270GF256C4? A: Yes, Intel offers development boards like the DE10-Lite board that can be used for prototyping and testing designs using EPM1270GF256C4.

Q: Can EPM1270GF256C4 interface with other components or devices? A: Yes, EPM1270GF256C4 supports various communication protocols such as UART, SPI, I2C, and Ethernet, allowing it to interface with other components or devices.

Q: What are the power requirements for EPM1270GF256C4? A: The power requirements vary depending on the design and usage, but typically EPM1270GF256C4 operates at a voltage of 3.3V or 1.2V.

Q: Are there any limitations or considerations when using EPM1270GF256C4? A: Some considerations include power consumption, heat dissipation, timing constraints, and the need for proper grounding and decoupling techniques to ensure reliable operation.

Please note that these answers are general and may vary based on specific design requirements and application scenarios.