GBU4A Diode Bridge Rectifier

Introduction

The GBU4A diode bridge rectifier is a crucial component in electronic circuits, serving the purpose of converting alternating current (AC) to direct current (DC). This entry provides an overview of the GBU4A diode bridge rectifier, including its product details, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Product Overview

- Category: Electronic Components

- Use: Rectifying AC to DC in electronic circuits

- Characteristics: High efficiency, low forward voltage drop, compact size

- Package: Through-hole or surface mount

- Essence: Converting AC to DC with minimal power loss

- Packaging/Quantity: Typically available in reels or tubes containing multiple units

Specifications

- Maximum Average Forward Current: 4A

- Peak Repetitive Reverse Voltage: 100V to 1000V

- Operating Temperature Range: -55°C to +150°C

- Storage Temperature Range: -55°C to +150°C

- Mounting Type: Through Hole or Surface Mount

- Package / Case: GBU

- Diode Type: Single Phase

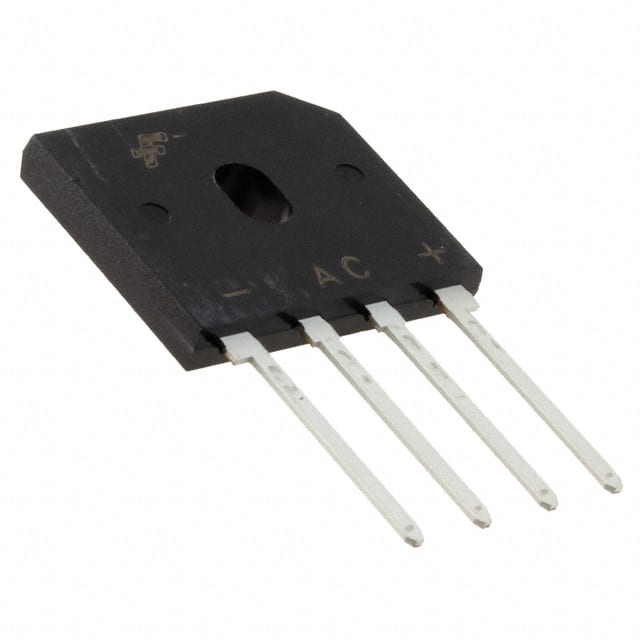

Detailed Pin Configuration

The GBU4A diode bridge rectifier typically consists of four pins arranged in a specific configuration. The pinout configuration is as follows: 1. Pin 1: AC Input + 2. Pin 2: AC Input - 3. Pin 3: DC Output + 4. Pin 4: DC Output -

Functional Features

- Efficiently converts AC to DC

- Low forward voltage drop minimizes power loss

- Compact design for space-constrained applications

- Reliable performance under varying temperature conditions

Advantages and Disadvantages

Advantages

- High efficiency in converting AC to DC

- Low power dissipation due to low forward voltage drop

- Compact size suitable for small electronic devices

- Reliable performance across temperature variations

Disadvantages

- Limited maximum average forward current compared to higher-rated diode bridge rectifiers

- Lower peak repetitive reverse voltage compared to some alternatives

Working Principles

The GBU4A diode bridge rectifier operates on the principle of utilizing four diodes in a bridge configuration to rectify the incoming AC signal into a smooth DC output. When the AC input cycles, the diodes conduct in such a way that the output remains predominantly positive or negative, resulting in a unidirectional flow of current.

Detailed Application Field Plans

The GBU4A diode bridge rectifier finds extensive use in various electronic applications, including but not limited to: - Power supplies - Battery chargers - Motor drives - LED lighting systems - Audio amplifiers

Detailed and Complete Alternative Models

Several alternative models to the GBU4A diode bridge rectifier include: - GBU6A: Higher maximum average forward current - GBU8A: Higher peak repetitive reverse voltage - GBU10A: Greater power handling capacity - GBU12A: Enhanced thermal performance

In conclusion, the GBU4A diode bridge rectifier is a vital component in electronic circuits, offering efficient AC to DC conversion with a compact form factor. Its specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models make it a versatile choice for various electronic designs.

[Word Count: 496]

기술 솔루션에 GBU4A 적용과 관련된 10가지 일반적인 질문과 답변을 나열하세요.

Sure, here are 10 common questions and answers related to the application of GBU4A in technical solutions:

What is GBU4A?

- GBU4A is a type of diode bridge rectifier commonly used in electronic circuits to convert alternating current (AC) to direct current (DC).

What are the typical applications of GBU4A?

- GBU4A is commonly used in power supplies, motor drives, and other electronic systems that require DC power from an AC source.

What is the maximum voltage and current rating for GBU4A?

- The maximum voltage rating for GBU4A is typically around 400 volts, and the current rating is usually in the range of 4 amps.

How does GBU4A differ from other diode bridge rectifiers?

- GBU4A is a specific model of diode bridge rectifier with its own unique electrical characteristics, packaging, and thermal properties.

What are the key features of GBU4A that make it suitable for technical solutions?

- GBU4A is known for its high efficiency, low forward voltage drop, and compact package size, making it ideal for space-constrained applications.

Can GBU4A be used in high-temperature environments?

- Yes, GBU4A is designed to operate reliably at elevated temperatures, making it suitable for industrial and automotive applications.

Are there any special considerations for mounting and heat dissipation when using GBU4A?

- Proper heat sinking and mounting techniques should be employed to ensure optimal thermal performance and long-term reliability of GBU4A in technical solutions.

What are the potential failure modes of GBU4A in technical applications?

- Common failure modes include thermal overstress, overvoltage conditions, and excessive reverse current, which can lead to degradation or permanent damage.

Can GBU4A be used in three-phase rectification applications?

- Yes, GBU4A can be configured in a three-phase bridge rectifier topology to convert three-phase AC power to DC power.

Where can I find detailed specifications and application notes for GBU4A?

- Detailed specifications and application notes for GBU4A can be found in the manufacturer's datasheet and application guides, providing comprehensive information for designing and implementing GBU4A in technical solutions.