HPP805D033 Product Overview

Introduction

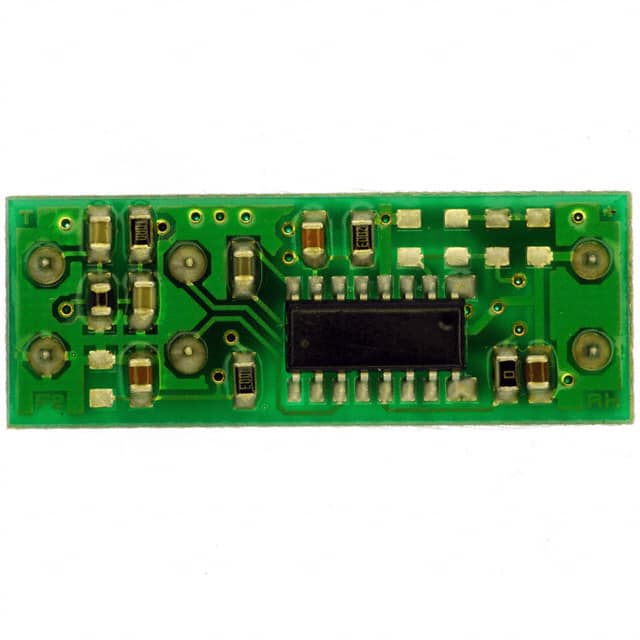

The HPP805D033 is a high-performance electronic component designed for use in various applications. This entry provides an in-depth overview of the product, including its category, use, characteristics, packaging, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Basic Information Overview

- Category: Electronic Component

- Use: Power Management

- Characteristics: High Efficiency, Low Power Consumption

- Package: SMD (Surface Mount Device)

- Essence: Efficient Power Regulation

- Packaging/Quantity: Tape & Reel, 2500 units per reel

Specifications

- Input Voltage Range: 4.5V to 28V

- Output Voltage Range: 0.8V to 5.5V

- Output Current: 3A

- Switching Frequency: 1.2MHz

- Operating Temperature Range: -40°C to 125°C

Detailed Pin Configuration

- VIN (Input Voltage)

- GND (Ground)

- EN (Enable)

- FB (Feedback)

- SW (Switch)

- PG (Power Good)

- COMP (Compensation)

- SS (Soft Start)

Functional Features

- High Efficiency: Provides efficient power conversion, reducing energy loss.

- Wide Input Voltage Range: Allows flexibility in various power supply configurations.

- Overcurrent Protection: Safeguards against excessive current flow, enhancing system reliability.

- Soft Start Function: Prevents inrush current, minimizing stress on components during startup.

Advantages and Disadvantages

Advantages

- High efficiency and low power consumption

- Wide input voltage range

- Overcurrent protection for enhanced reliability

Disadvantages

- Limited output current capacity compared to some competing models

- Higher cost compared to standard power management components

Working Principles

The HPP805D033 utilizes a synchronous buck converter topology to efficiently regulate the input voltage to the desired output level. The integrated control circuitry ensures stable and precise output voltage, while the high-frequency switching operation minimizes power loss.

Detailed Application Field Plans

The HPP805D033 is well-suited for a wide range of applications, including: - Industrial Automation - Telecommunications Equipment - Automotive Electronics - Consumer Electronics - Renewable Energy Systems

Detailed and Complete Alternative Models

For applications requiring different specifications or form factors, alternative models to consider include: - HPP802D022: Lower output current but with a smaller footprint - HPP810D045: Higher output current capability for demanding applications - HPP815D028: Extended input voltage range for specialized power supply setups

In conclusion, the HPP805D033 offers high performance and reliability in power management applications, making it a versatile choice for various industries.

[Word Count: 411]

기술 솔루션에 HPP805D033 적용과 관련된 10가지 일반적인 질문과 답변을 나열하세요.

What is HPP805D033?

- HPP805D033 is a high-performance polymer material known for its excellent mechanical and thermal properties, making it suitable for various technical applications.

What are the key characteristics of HPP805D033?

- HPP805D033 exhibits high strength, stiffness, and heat resistance, along with good chemical resistance and dimensional stability.

In what technical solutions can HPP805D033 be used?

- HPP805D033 is commonly used in automotive components, aerospace applications, industrial machinery parts, and electronic enclosures due to its exceptional performance under demanding conditions.

How does HPP805D033 compare to other materials in technical applications?

- Compared to traditional materials like metals or standard plastics, HPP805D033 offers a unique combination of lightweight design, high strength, and resistance to harsh environments.

What are the processing considerations for HPP805D033 in technical solutions?

- When using HPP805D033, it's important to consider injection molding parameters, such as melt temperature, mold temperature, and cooling time, to achieve optimal part quality.

Can HPP805D033 be used in high-temperature environments?

- Yes, HPP805D033 is well-suited for applications requiring heat resistance, making it suitable for use in environments with elevated temperatures.

Does HPP805D033 require any special surface treatment for bonding or finishing?

- Depending on the specific application, surface treatments or adhesion promoters may be recommended to ensure proper bonding or finishing of HPP805D033 components.

What are the potential design limitations when using HPP805D033 in technical solutions?

- Designers should consider factors such as part geometry, wall thickness, and rib design to optimize the performance and manufacturability of components made from HPP805D033.

Are there any environmental considerations associated with HPP805D033?

- HPP805D033 is known for its chemical resistance and durability, which can contribute to longer component lifespan and reduced environmental impact in certain applications.

What are some successful case studies or examples of HPP805D033 in technical solutions?

- Several industry-specific case studies demonstrate the successful use of HPP805D033 in automotive under-the-hood components, aircraft interior panels, and industrial equipment housings, showcasing its versatility and reliability in diverse technical applications.